PROCESS CONTINUOUS IMPROVEMENT ENGINEERING

PROCESS CONTINUOUS IMPROVEMENT ENGINEERING

1. KAIZEN IMPROVEMENT

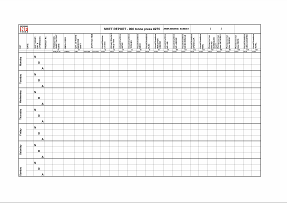

2. PROCESS IMPROVEMENT SELECTION BY A MATRIX

3. PRODUCTION OR MAINTENANCE EFFICIENCIES ANALYSIS

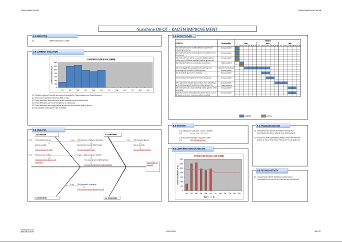

KAIZEN IMPROVEMENT

1.0 OBJECTIVE

Clear simple description

2.0 CURRENT SITUATION

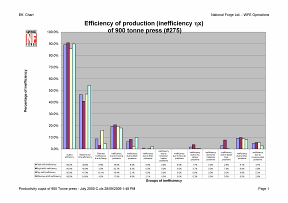

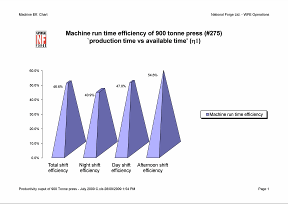

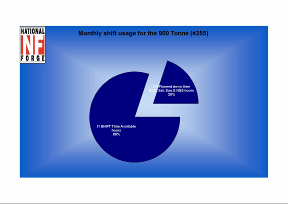

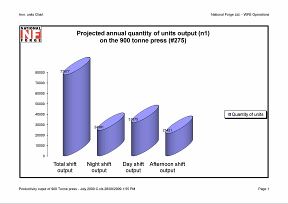

Bar graph of values and points arising from the situation

3.0 ANALYSIS

Fish bone chart with 3.1.0 PERSON, 3.2.0 MATERIAL, 3.3.0 METHOD & 3.4 .0 MACHINE

4.0 ACTIVITY PLAN

Gantt chart

5.0 SAVINGS

Points arising from savings and simple calculations

6.0 CONFIRMATION OF RESULTS

Bar graph of values and target line

7.0 STANDARDISATION

Points arising for standardisation

8.0 FUTURE ACTIVITY

Points arising for future improvement

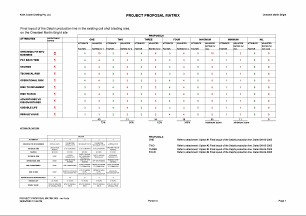

PROCESS IMPROVEMENT SELECTION BY A MATRIX

Project proposal Matrix

Attributes that are critical for the business are listed by a steering group, including the attribute factors that are used for scoring a selection

A number of different proposals for the single project would be tabled

Independent persons of the steering group review and score each of the tabled proposals

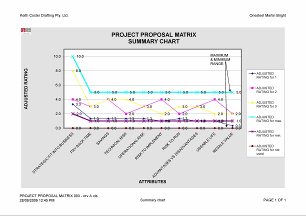

A summary line graph displays how the each different proposal scored.

This is a clinical way of choosing a suitable project within a group.